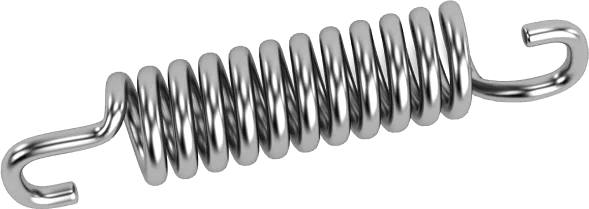

Helical Coil Spring

Helical Coil Spring is a coiled wire wound mechanical device into a helix shape. It is designed to absorb and store energy, resisting compressive or tensile forces. These springs are commonly used in various applications, including automotive suspensions, machinery, and electronic devices.

Helical Coil Spring is called safety items because they help absorb shock, reduce vibrations, and prevent damage to other components, ensuring smooth operation and extending the lifespan of equipment. Helical coil springs protect the system and its users from potential harm by managing stress and strain.

Helical Coil Spring manufacturers :

● We are Helical Coil Spring manufacturers upto the following capacity :

Wire Dia. – upto 70 mm.

Outer Dia. – upto 500 mm.

Free Height – upto 1000 mm.

Total Coils – As per user’s requirement.

Load Capacity – upto 40 Tons. (per pc.)

● Raw-material grades used in Helical Coil Spring manufacturing : Spring Steels as per Indian standard – BS:970 EN-42, BS:970 EN-45, BS:970 EN-47, 50Cr.V4, 50Cr.4V2, 51Cr.V4, 50Cr.MoV4, 50Si7, 55Si7, 60Si7, SUP-9, SUP-9A, SAE-5160, IS:4454 Part-1 Grade-2, IS:4454 Part-1 Grade-2D, Stainless Steel etc. and others similar foreign grades JIS, ASTM etc.

● Painting and Coating used for Helical Coil Spring making : Synthe2tic Enamel Paint, Powder Coating, Phosphate, Zinc Coating etc.

Why are we a top Helical Coil Spring Exporters ?

● Uncompromising quality : We prioritize superior quality of Helical Coil Spring at every stage of production. Our commitment to using high-grade raw materials, conducting rigorous stage inspections, and adhering to precise dimensions ensures that our helical coil springs meet the highest standards. Our heat treatment processes are meticulously applied to enhance performance and longevity. As an ISO 9001:2015 certified company, we uphold the highest quality management practices.

● Competitive pricing : We offer a comprehensive range of Helical Coil Springs at competitive prices, ensuring value for your investment without compromising quality. Our efficient manufacturing processes and supply chain management enable us to provide cost-effective solutions.

● Guaranteed performance : Our Helical Coil Springs are designed and tested for reliable and consistent performance. We stand behind our products with guarantees, ensuring they meet the performance specifications required for your applications.

● Extensive experience : With years of industry experience, we have honed our expertise in designing and manufacturing Helical Coil Spring. Our long-standing presence in the market reflects our deep understanding of industry needs and technological advancements.

● Global user feedback : Our Helical Coil Springs are trusted by users worldwide. Positive feedback from a diverse range of customers underscores our commitment to quality and customer satisfaction, reinforcing our reputation as a leading manufacturer in the global market.

GET IN TOUCH WITH US

CONTACT INFO.

- Regd. Address : 11/3, Kedarnath Deauty Lane, Kadamtala, Howrah - 711101, West Bengal, India

- Call us : +91 9339332646 / +91 9831362048

- Email : [email protected]